Job Shop

Job Shop

Job Shop

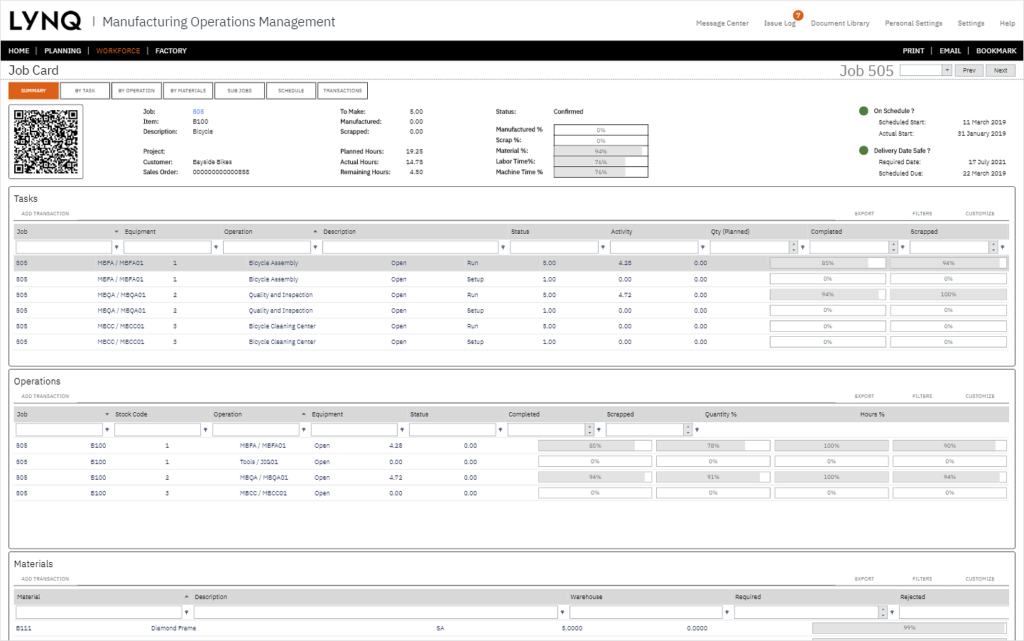

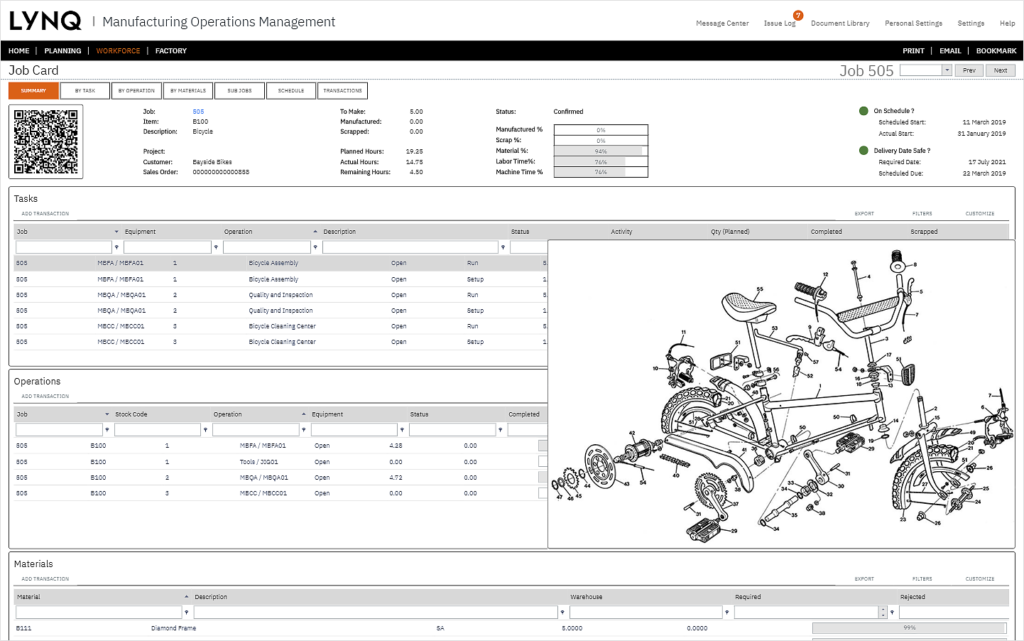

Custom product/one off

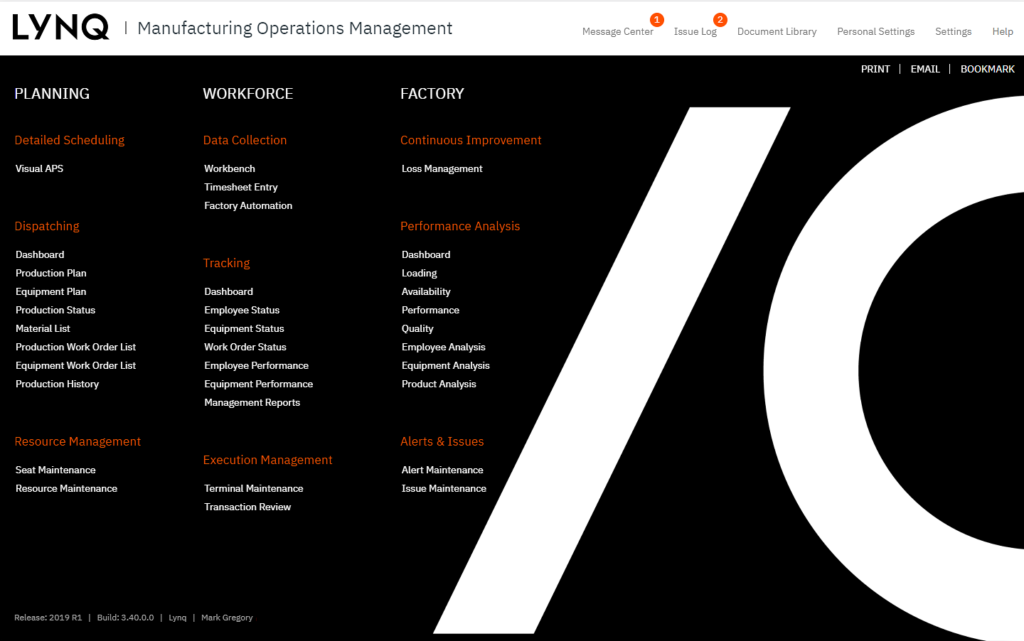

Design > Calculate > Quote > Source > Make > Deliver

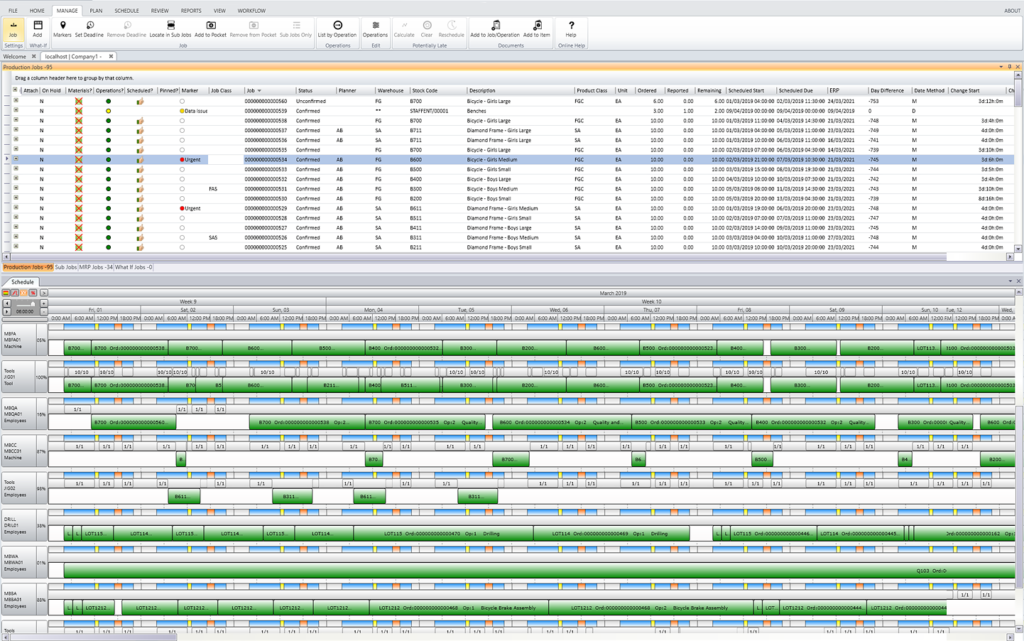

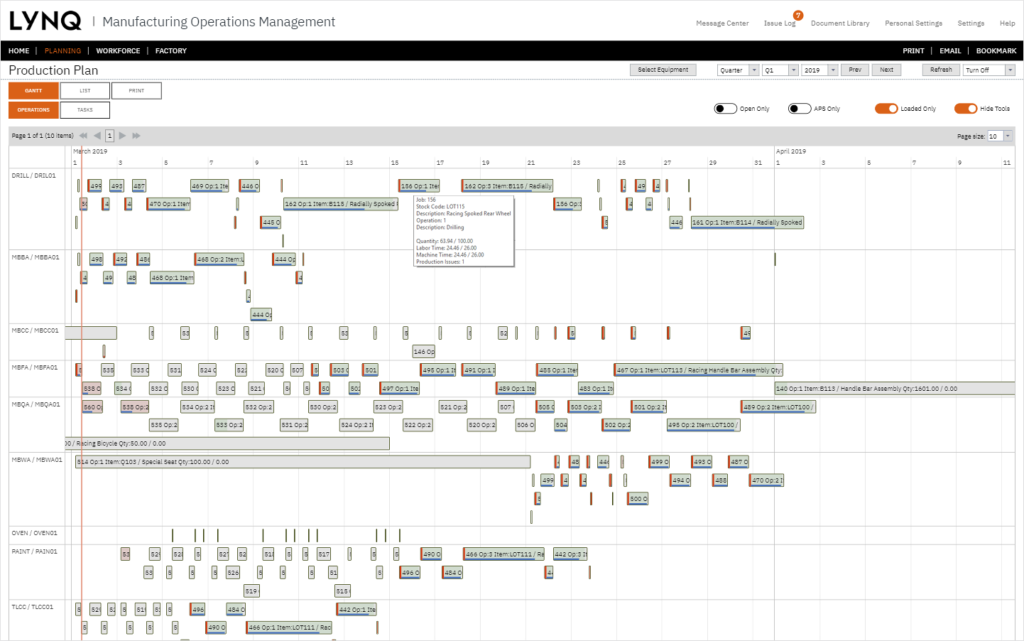

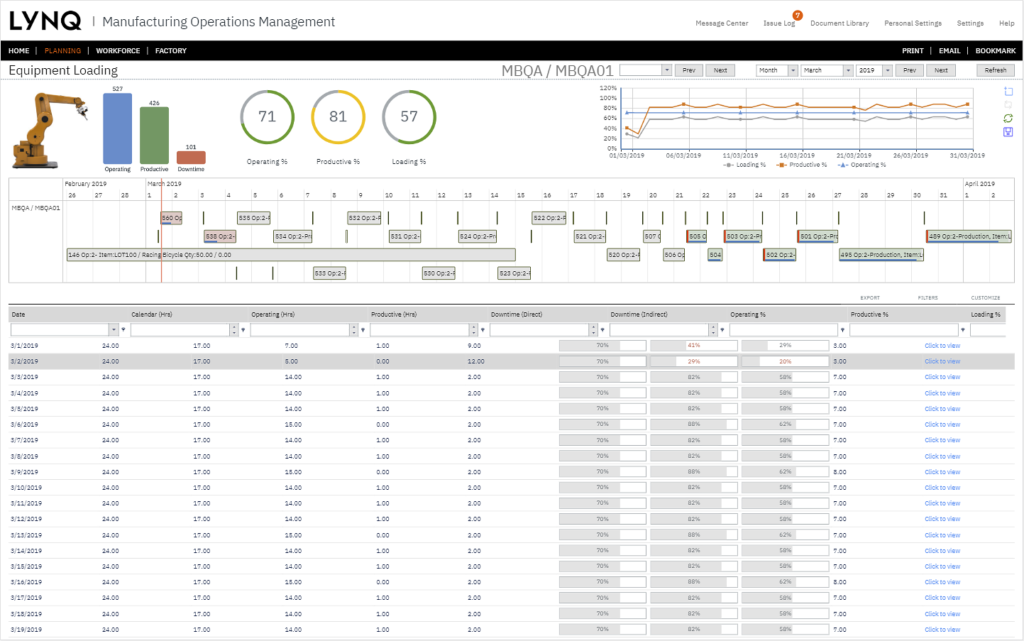

- Capable to Promise – ability to determine the delivery date of potential orders by overlaying them on the existing plan

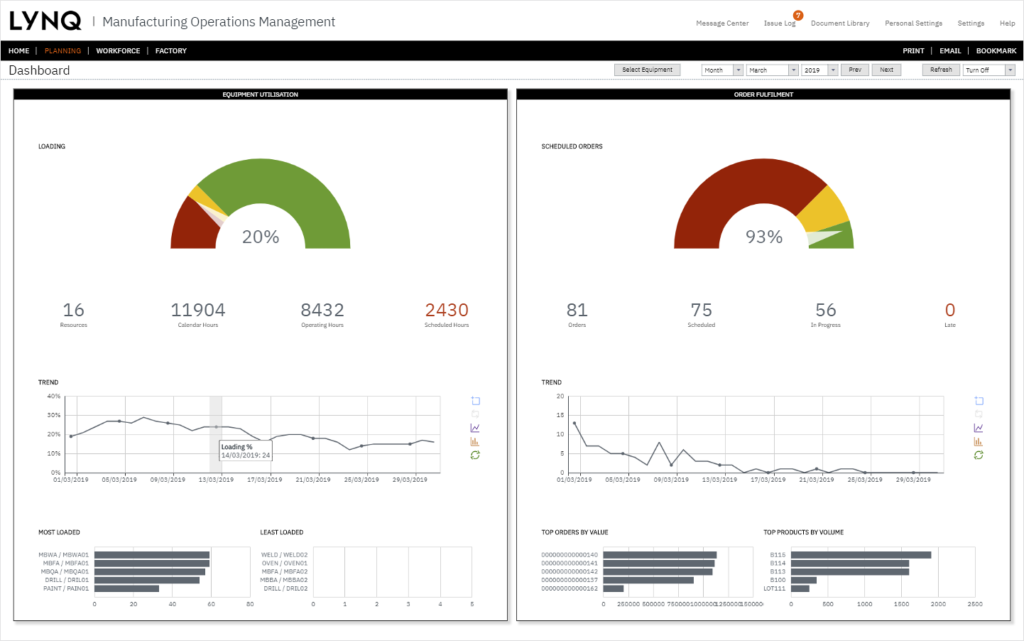

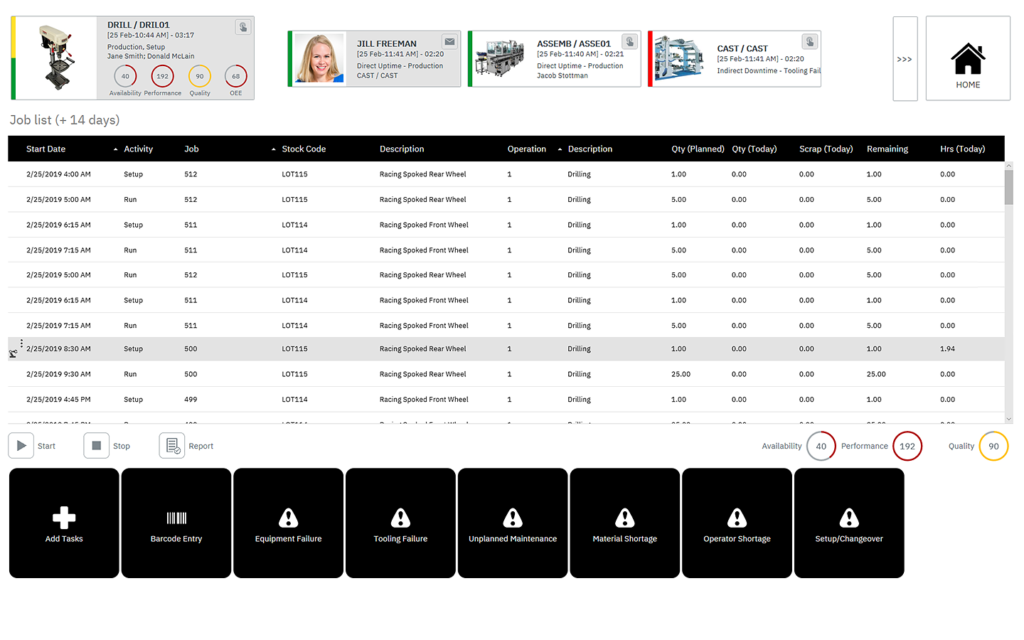

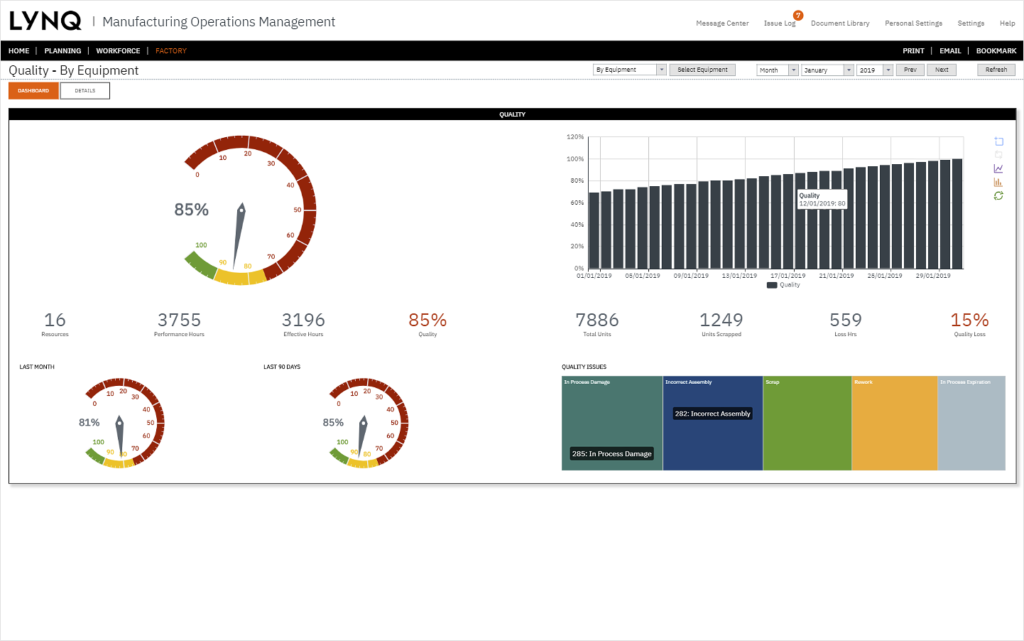

- Accurate job costs – ability to collect data easily and accurately to determine accurate job status and costs for margin and/or profit analysis

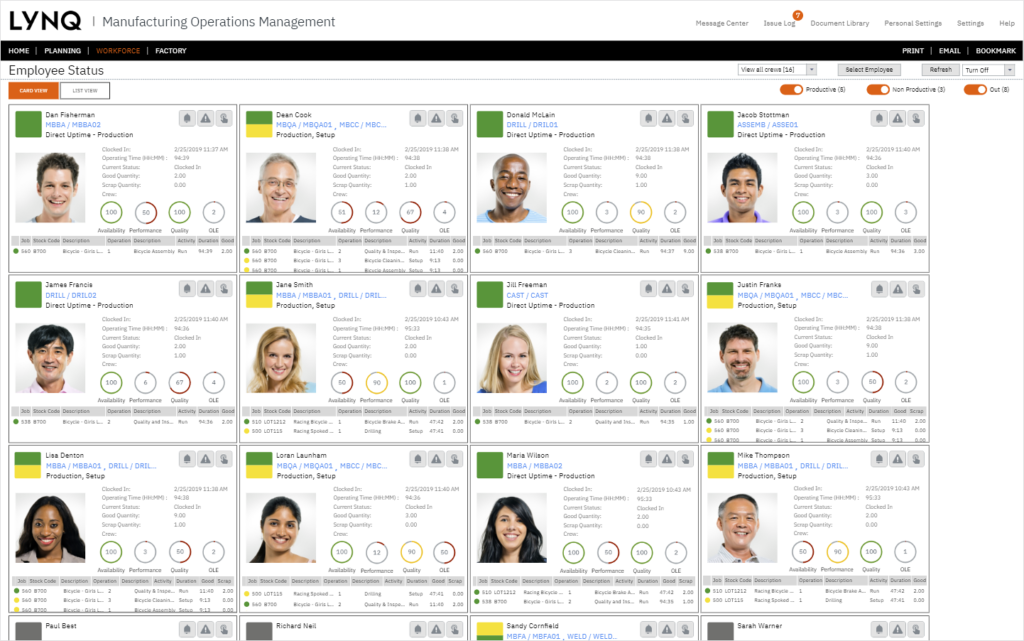

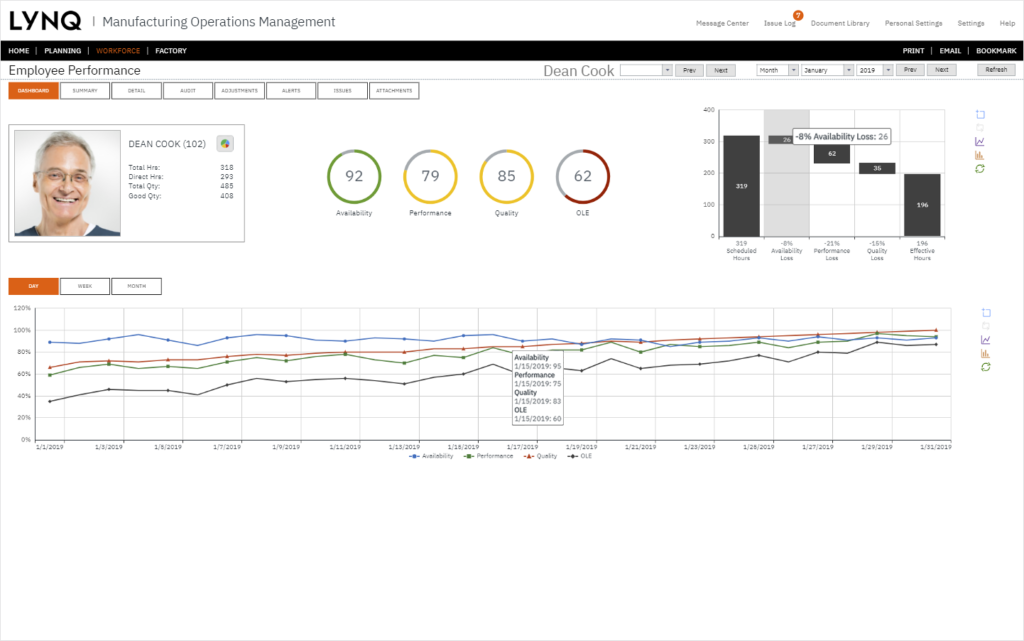

- Employee utilisation – ability to analyse and make the best use of high cost, skilled employees (OLE)