Proven by

your peers.

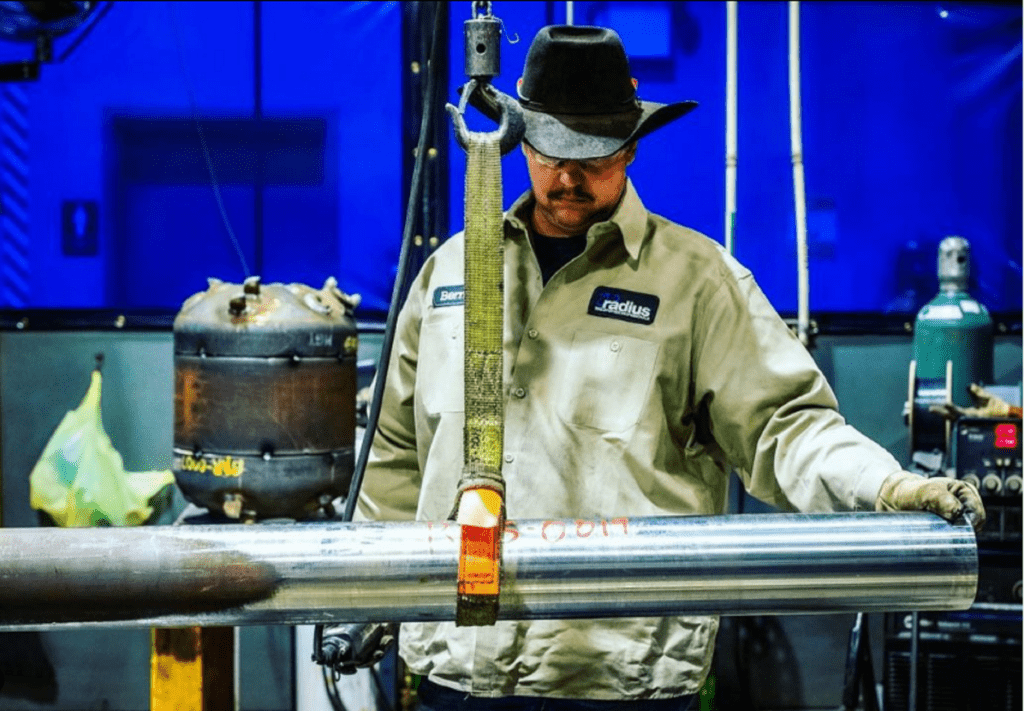

Radius HDD: Supporting Business Growth through LYNQ MES

Horizontal direction drilling tools company, Radius HDD cut their production time down by 30 hours a week through LYNQ!

Innovative drill tools company, Radius HDD (Horizontal Direction Drilling) Tools’ growth strategy was hindered by manually driven, access-based, difficult-to-use planning that took a lot of effort and time. LYNQ’s Manufacturing Execution System (MES) helped the company set up their team for success by giving them digital tools for scheduling and an online-based production plan. This benefitted their entire manufacturing operation, ensuring the whole team is working on one plan that is visually accessible and updated in real-time, from the Production Planners laptop to the machine screens on the shop floor.

The data collection aspect of LYNQ has greatly assisted Radius’ reporting needs to provide visibility into their production hours and understand where losses can be minimised.

About Radius HDD

Radius HDD (Horizontal Direction Drilling) is committed to bringing innovative HDD tools and services to the directional drilling industry.

Radius HDD was founded by working directly with contractors to address the problems drillers were having with their existing tools. In no time, Radius was building the best rock tools in the business.

Radius now produces more than just rock tools, added to their list of tools are reamers, customs subs and much, much more. Radius offers a complete line of superior tools to HDD professionals worldwide through a comprehensive industry catalogue and website. The secret to their success is that they’ve never stopped working with drillers in the field.

“LYNQ MES is great for us as it can optimise the way things need to run in a sequence that makes the most sense, it’s really changed the dynamic of how we solve issues and has had a huge impact on how efficiently we can work.”

Steve Taylor, Head of Operational Activities

The Goal

Being a $30 million company with ambitions to grow to $100 million, they needed a better understanding of their equipment utilisation and to compare that against their labour utilisation. To build a better experience for their customers, their whole technology platform needed to be looked at.

- Gain real-time visibility into time spent on certain products

- Overall cost saving

- Collect data for reporting and optimising

- Scheduling their manufacturing process

Key Benefits

Digitalisation – the company is now able to move away from manual and paper-based manufacturing management which consumed so much of its time.

Visibility of planning and capacity – the process was admin and labour intensive, with limited reporting. They are now able to track each job electronically and have clear visibility of labour and machine capacity in real-time.

LYNQ MES has digitalised the entire process for Radius HDD. Equipping them with control over their manufacturing operations and the data to be able to report back on and utilise time more efficiently.

Your industry.

Understood.

Unleash your potential.

resource management.

"*" indicates required fields