Proven by

your peers.

ACI Services: Saving Time and Digitalising Processes

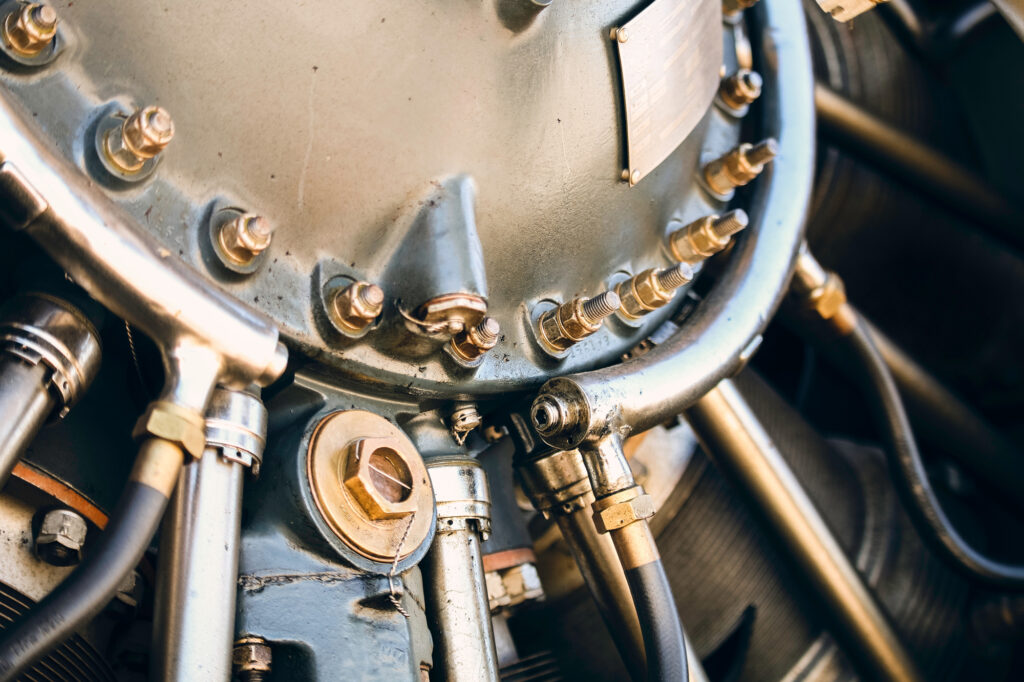

Oil and gas components manufacturer, ACI, eradicate manual, paper-based data entry and take back control of scheduling through LYNQ MES.

ACI Services Inc.’s design and manufacturer natural gas components for the oil and gas industry in the United States, selling worldwide. The company provides manufactured products, engineered solutions and performance software for reciprocating compressors.

Since implementing LYNQ MES, ACI have vastly improved their visibility of manufacturing capacity and gained the confidence to know exactly what can be produced and when. Previously using a manual, paper-based system the financial implications of using LYNQ MES have been significant, improving their service to customers through accurate quotes and optimising their business as a whole through precise product margin calculations.

LYNQ MES at ACI Services

Key Benefits

Time savings – before LYNQ, 3 people’s time was consumed with manual data entry. This is now completely eliminated through LYNQ’s employee and machine tracking.

Confidence and control over capacity – can now accurately and visually see where they are, capacity wise, with new orders automatically updating the production schedule.

Business-wide impact – improvements in both costings and margins has greatly improved accuracy of financial reporting and insight into where savings can be made.

Why LYNQ MES?

LYNQ delivered on a key functional need for ACI and has continued to benefit the whole business.

“LYNQ was a natural fit for us because our requirement was to be able to see the schedule and capacity over a period of time and see how a new order would affect this. This had become a business necessity for us.”

“Knowing our true schedule for the machine shop and the assembly side is the biggest benefit for me. LYNQ is eye candy for us to see where we stand for the day or month.” Adam Bright, ACI Master Scheduler.

“The time we’ve saved in data entry is tremendous. We had 3 people’s time to do nothing but data entry. Now the guys just click go and stop. LYNQ has eliminated that manual data entry process completely.”

Pandu Badam, Manufacturing Project Manager

Your industry.

Understood.

Read the full customer success story

Read moreMore on component manufacturing

Industrial equipmentHear from more

LYNQ MES customers

Customer stories Unleash your potential.

resource management.

"*" indicates required fields